Fully Automated High Speed 3 Ply Disposable Flat Mask Material Cutting Machinery Mask Machinery

Basic Info

| Model NO. | LQ-008 |

| Warranty | Core Component with 1-Year Warranty |

| Application | Mask |

| Automatic Grade | Automatic |

| Certification | CE, ISO9001: 2000 |

| Customized | Customized |

| Condition | New |

| Province | Zhejiang |

| MOQ | 1 Set |

| Voltage | 220V |

| Power | 0.75kw |

| Weight | 370kgs |

| Transport Package | Plywood Wooden Case Packing |

| Specification | 470mm(L)*350mm(W)*200(H) |

| Trademark | KYY |

| Origin | China |

| HS Code | 8449009000 |

| Production Capacity | 5 Sets/Day |

Packaging & Delivery

Package size per unit product 67.00cm * 55.00cm * 40.00cm Gross weight per unit product 470.000kgProduct Description

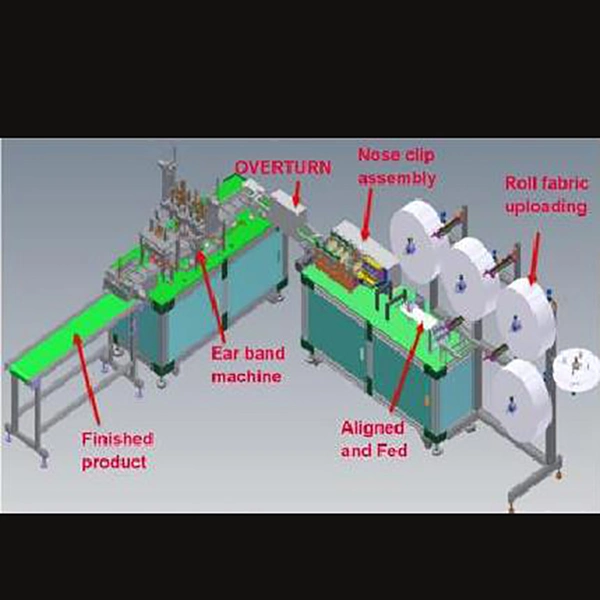

Fully automated high speed 3 ply disposable flat mask material cutting machineryOne drag one automatic flat mask machine production line

1). Operation manual

1. It is suitable for producing disposable face mask.

2. Whether the mask produced by the secondary production line is medical or not has nothing to do with the machine. As long as the mask is sterilized and analyzed, the mask produced by this production line can be used as surgical mask.

3. We can produce different sizes and styles of masks by changing the mold.

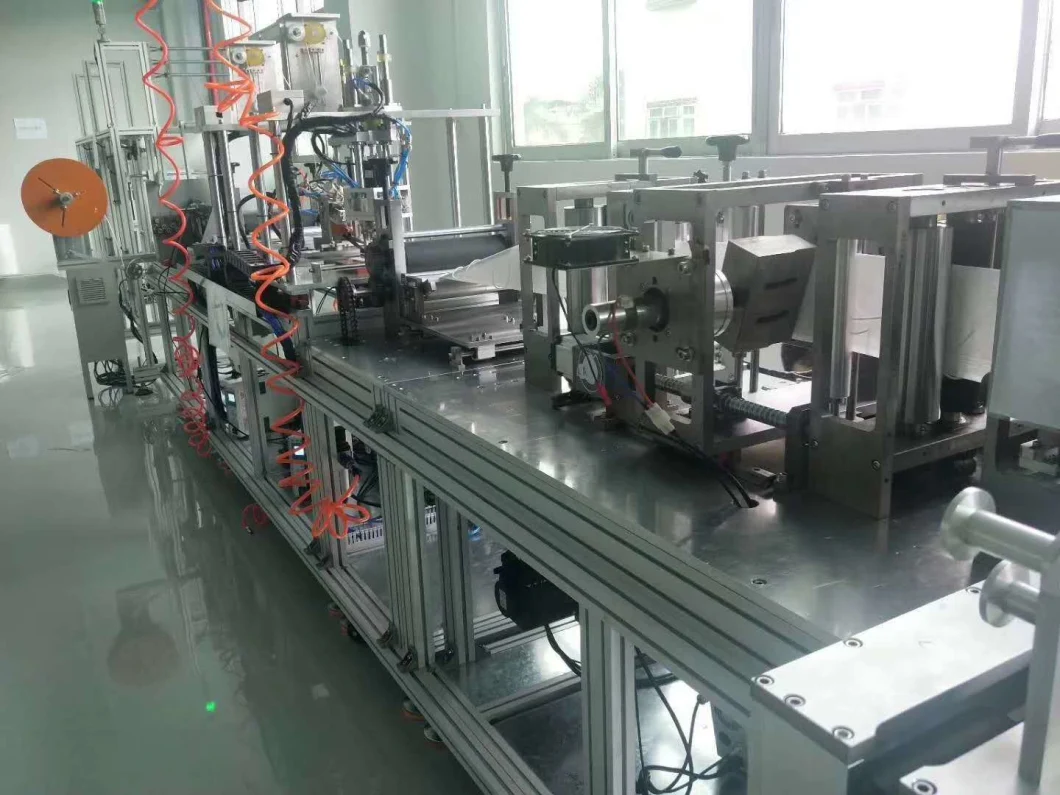

4. The plane mask production line adopts aluminum alloy structure, with good finish and no rust.

After two days of on-site training or video teaching, users can independently complete machine debugging and production operation.

1. Automatic delivery of raw materials

2. Automatic delivery of raw materials

3. Automatically cut off the bridge of nose

4. Length direction edge welding of respirator

5. Hem

6. Forming shear

7. Blanking

3) Automatic high-speed plane ear belt mask production line, including automatic delivery of raw materials, automatic delivery, cutting nose strip, mask edge welding, folding, ultrasonic fusion, forming, cutting and other full process automation, complete the whole production process from raw materials roll to finished products of mask.

1. The production line of high-speed full-automatic one drag one plane mask machine is connected by one main body machine and one belt machine. After the body machine outputs the mask body, the conveyor belt structure will transfer the mask body piece to place the mask piece in the mask plate of the ear belt machine, and then the ear belt machine will complete the ear belt fusion of the mask, so as to complete the production of one ear belt mask product.

2. The high-speed full-automatic one drag one plane mask machine production line is mainly used for automatic forming of plane masks: the whole roll of cloth is driven by the roller after unwinding, and the cloth is automatically folded and wrapped; the nose strip is pulled and uncoiled by the whole roll, cut to a fixed length and then introduced into the wrapped cloth, and the two sides are welded to the seal by super sound, then sealed laterally by ultrasonic, and cut to shape by the cutter; the cloth is formed by flowing water The line will transfer the mask to two mask ear belt welding stations, and the final mask will be formed by ultrasonic welding; when the mask is made, it will be collected by the assembly line to the flat line.

Zhejiang Longqi Science and Technology Group with five subsidiaries is a collection of production, research and development, sales as one of the diversified developing enterprise. Zhejiang Longqi Science and Technology Group Wenzhou Jinghong International Trade is one of the subsidiaries. We have 3 main brands, KKK, KYY and KIKI. Our company produces all kinds of zipper slider parts, Metal,nylon,plastic full-auto zipper pre-processing, latter equipment, auxiliary equipment, to meet the different needs of different customers. We also produce all kinds of clothing accessories and luggage bag accessories, zipper slider equipment and various equipment accessories.There are all kinds of zipper sliders, bag zipper slider universal assembly machine, universal assembly machine for bag zipper slider and keyhole, special die casting machine for zipper sliders, straight shrapnel capping machine, automatic rolling and returning material machine, automatic assembly machine for invisible puller, spring head assembly machine, automatic assembly machine for bag zipper sliders, automatic assembly machine for spring fastener, barrel polishing machine, paint spraying machine, polishing machine grinding machine, etc., can also be customized.https://kyyzipper.en.made-in-china.com/

Q1: Wonder if you accept small orders?

A1: Do not worry. Feel free to contact us .In order to get more orders and give our clients more convener ,we accept small order.

Q2: Can you send products to my country?

A2: Sure, we can. If you do not have your own ship forwarder, we can help you.

Q3: Can you do OEM for me?

A3: We accept all OEM orders,just contact us and give me your design.we will offer you a reasonable price and make samples for you ASAP.

Q4: What's your payment terms ?

A4: By T/T,LC AT SIGHT,30% deposit in advance, balance 70% before shipment.

Q5: How long is your production lead time?

A5:It depends on product and order qty. Normally, it takes us 15 days for an order with MOQ qty.

Q6: When can I get the quotation ?

A6: We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation.Please call us or tell us in your mail, so that we could regard your inquiry priority.

![LDT-SRP Mattress Roll Packing Machine Mattress Compression Machine Mattress Packing Machine [easy to install,operate and maintain]](/uploads/s/4c84fb2079ac4fcf8d901728357213de.webp)